TIME-SERT Insert VS NorthStar “Stud” Type Repair Kits

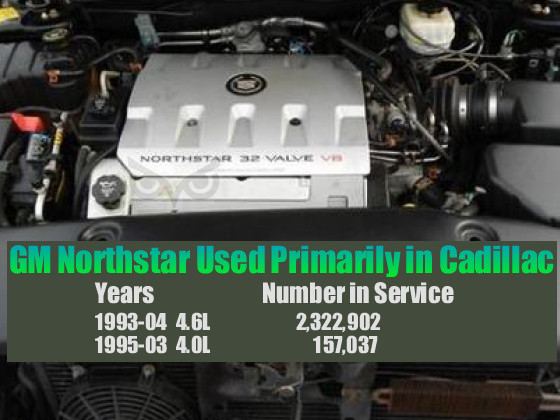

Originally posted on our previous blog 10/10/13 DennisB WiseAutoTools.com © Summary: Cadillac NorthStar head bolt thread failures are common in 4.0 and 4.6 engines, from 1993 and up. Aluminum blocks which are very common these days are mostly to blame. But what’s the best repair? We look at the GM approved method compared to the Northstar Performance “stud” type repair kit, which has only been used on a relatively small number of vehicles. We looked into studs and question why Cadillac engineers decided NOT to go with that method to fix the problem and why they went with the Time-Sert brand as their preferred method. Time-Sert uses a steel threaded bushing type insert, which allows the original type TTY (Torque to Yield) head bolts to be used.

Kent Moore which is GM’s OEM tool brand also sells the TIME-SERT in their tool line (however at a higher cost). In fact Time-Sert is listed among some of the Cadillac dealership’s required tooling, called special service tools. Special service tools are certain specialty tools required by car manufacturers for dealerships to have at their service centers in order for the dealer to comply with minimum requirements. If they don’t comply by purchasing the required special service tools the dealership may not be granted to begin with; or the franchisee risks losing their dealership. This is simply to assure the best, most dependable repairs can be completed and to uphold the highest possible customer satisfaction. Time-Sert did not design their thread repair system in a lone machine shop. They actually worked together with GM’s engineers to design a repair which kept the critical clamping features of the TTY bolts which also increased the strength of the threads holding them exponentially. In the year 1998, the J-42385 series of thread repair kits were developed in cooperation with GM Powertrain as an improved and preferred method of thread repair. Let’s explore a little further.

Question: What are the demands or requirements of the head bolt?

Answer: Head bolts are a critical fastener that are required to handle extreme conditions to prevent the head gasket from leaking compression, coolant, oil and exhaust gases. It’s estimated that each head bolt must withstand several tons of pressure, especially at wide open throttle. And the head bolts must expand when the engine is at operating temperature a pre-determined amount. This tolerance has been determined by an engineer. Also the head bolts must contract within a certain tolerance. Too much off on either end of the spectrum and there can be a leak when cold or when hot.

Question: Isn’t tighter always better?

Answer: Due to the tolerances mentioned above, tighter is not always better. In fact with heat expansion considered “too tight” might cause something to fail. Either threads pulling, or blocks cracking. The use of TTY bolts help to maintain the correct torque as opposed to studs which are not TTY.

Question: Are the aftermarket studs sold by some companies TTY?

Answer: At this time no aftermarket “studs” are TTY. On one of the aftermarket stud company’s website for Northstars there’s not a single mention or acknowledgement of TTY bolts or studs. Only the original type head bolts are TTY. In fact Fel Pro (which sells aftermarket parts) buys head bolts for the Northstar directly from the OEM manufacturer and packages them with their labeling. The cost to reproduce head bolts with the specific characteristics and specifications would cost more than going straight to the original source.

Question: I read on NorthstarPerformance.com that their kits are authorized by GM.

Answer: I saw that myself. It said “We have great news! General Motors has approved our kit for warranty repairs!” – but apparently they were asked to remove that statement because it no longer says that. Neither does it say ZERO failures… removed also.

Question: The Northstar stud company’s website says their stud has a larger diameter at the bottom which goes in the block. Since the base of the stud is secured in a larger area in the block, doesn’t that make it stronger/superior?

Answer: What you’re asking is; Isn’t a larger O.D. (Outside Diameter) better? Sounds logical at first. However, the block is not made of solid stock. It has cylinders, oil passages and coolant passages. That makes it thinner at some points than others. In fact the GM Northstar TSB which says to use the TIME-SERT kit as their only authorized warranty repair; only recommends the regular size and does not authorize the use of BIG SERT’s. BIG SERTs are TIME-SERT’s oversize version for second time repairs. Second time repairs are typically done when a Helicoil or competing brand insert has failed. The quote below is from GM’s Northstar head bolt thread repair TSB.

This larger size insert cannot be used for warranty repairs. Due to the increased O.D. of this sert, it’s possible that when installing this larger sert that it will break out in the water jacket causing a coolant leak.

That was particularly true from 1996 and prior. GM, since then, has improved the quality of the aluminum used in the Northstar engine blocks. WiseAutoTools.com doesn’t recommend going with a BIG SERT on a virgin repair because we think it is important to leave as much aluminum in the block as possible because it will surely be stronger. However, if faced with replacing the block or using the BIG SERT kit (like the J-42385-500BS) we recommend using the BIG SERT kit, especially on 1997 models and above. If a stud fails there is no second chance because the stud diameter is so large to begin with, there is no more material to work with. Also there’s an increased chance of the block cracking since the material is so thin after a stud type repair has been made because the installer has to drill out so much aluminum. With the stud kit, the disturbing thing is they even say in their instructions that hitting the studs with a hammer may crack the block. Why would you want to hit the studs to begin with? Because their studs may not line up with the holes in the cylinder head. Here’s a quote from the aftermarket Northstar stud company’s directions.

In the unusual event that one or more studs is out of alignment, you can very carefully ease them into position by installing a nut to protect the threads and giving soft but firm blows to the stud with a rubber mallet.

DO NOT USE A STEEL HAMMER OR YOU MAY CRACK THE ENGINE BLOCK!

This is a common practice and will not damage or crack the engine block if done with the proper rubber mallet.

Something about “in the unusual event” and “it’s a common practice” doesn’t quite ring true. Nothing makes me more skeptical than when the directions tell me to whack something with a hammer to MAKE their product work. And like with most warnings… I suppose someone cracked their block by hitting on the studs in an attempt to make the head fit over the studs. Just a guess.

Our Conclusion: GM and TIME-SERT engineers have spent a lot of time and effort to design the best possible repair for Northstar engines. The first J-42385 series kits were recommended by GM for Cadillac in 1998. No need to re-create the the wheel so to speak. GM dealers are currently receiving their brand new TIME-SERT head bolt thread repair kits for the new Northstars. The LS9 uses M12x1.75mm. This is a testament that GM still only uses TIME-SERT for their warranty repairs and TIME-SERT is the ONLY authorized repair by GM for many reasons. GM still even after all these years has TIME SERT (Time Fastener Company) develop thread repair solutions – GM authorizes no other company for head bolt thread repair.

See our Northstar and other related TIME-SERT thread repair kits which have been tested and are exclusively approved by GM. We offer free fast shipping within the USA on certain TIME-SERT products. Special deals everyday and bulk pricing for replacement inserts. See product listings for details.

7/29/21 - Update to article. Northstar Performance contacted me by phone today and wanted our article removed. He claimed to be the owner of the company that produces the stud type repair that was in our article. I asked what in particular he took issue with? Nothing specific. I asked if anything was inaccurate or if the instructions for his kit has changed? No, he just wanted me to remove the article and threatened legal action. I asked if his stud kits use TTY bolts as GM has designed. He said no, GM TTY bolts are junk, why would I use them? I explained that something has to give. It's my understanding that TTY bolts stretch as to not put undue stress on the cylinder head and block, while keeping a constant clamping action during different heat ranges. Full disclosure, we sell Time Sert kits obviously; and have stated our opinions in our blog article. For the moment, differing opinions on products are allowed in the USA the last time I checked.

Related – Visit either of our website’s DenLorsTools.com or WiseAutoTools.com or Call to order 800-734-8665

J-42385-500 Works on early Northsar engines. M11x1.5 installs 11155 inserts.

J-42385-2000 Works on later model Northstar engines. M11x1.5 installs 11155 inserts.

2200 Universal Kit. This is our choice because it covers all of the M11x1.5 Northstar engines and works for Honda, Toyota and many others that use M11x1.5 head bolts. It installs the same M11x1.5 pn 11155 inserts. What makes it different is that the depths are adjustable unlike the specific Northstar kits listed above.

Recent Posts

-

Shorter Kits for Head Bolt Thread Repair - What are the downsides?

We recently came across an article that stated the more expensive, longer Time Sert kits made for he …28th Feb 2024 -

Polaris Head Bolt Thread Repair Kit - Information and Recommended Kit & Inserts

Aluminum head bolt threads pulling out on Polaris engines is a fairly common problem. Installing a s …23rd Jan 2024 -

How Bad Can Spark Plug Hole Erosion Get, and Can It Be Fixed?

How severely can a spark plug hole in an aluminum engine head, which previously had a repair insert …5th Dec 2023